In this installment of our “Meet the Models” series, we’ll pull back the curtain on the machine‑learning systems that power Uplight’s Flex DERMS platform. Here we’ll dive into our Predictive Capacity Dispatch (PCD) capability—the AI engine that transforms hundreds of thousands of distributed energy resources (DERs) into a single, reliable virtual power plant for utilities.

The Case for Smarter, More Predictable Demand Response

Utilities are under growing pressure as demand peaks become more extreme, grid conditions more volatile, and demand-side technologies more complex. Peak electricity demand is rising faster than average load in many areas, driven by a combination of hotter summers, trends in electrification, and growing reliance on intermittent renewables.

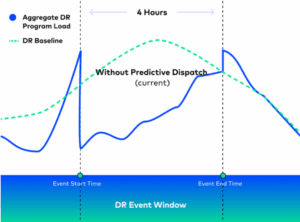

At the same time, adoption of distributed energy resources (DERs) such as smart thermostats, electric vehicles, and behind-the-meter batteries is accelerating. While these devices offer flexible load that could help manage peak demand, their performance during traditional demand response events is highly variable. Smart thermostats, for example, may shed significant load in the first hour of an event, but their impact often declines in subsequent hours due to thermal fatigue or customer opt-outs. This degradation in load shed performance over the hours of a traditional demand response event results in an unfortunate reality: even with high levels of penetration in North America, traditional thermostat DR is often unable to provide the level of predictability and reliability required in the utility control room.

That unfortunate reality with traditional thermostat DR presented our Data Science and Engineering teams at Uplight with a challenge: How do we transform fleets of small, residential DERs into a single “virtual capacity resource” that delivers predictable, firm load reduction in aggregate, over long demand response event periods?

The Solution: Predictive Capacity Dispatch

To solve the challenges of traditional demand response, Uplight has developed Predictive Capacity Dispatch (PCD)—a smarter, more adaptive approach to orchestrating distributed energy resources, including smart thermostats. PCD shifts the paradigm from one-size-fits-all control to targeted, data-driven coordination that accounts for each device’s unique behavior and limitations, and each customer’s unique preferences. At its core, PCD is designed to deliver consistent, reliable load reduction across a population of DERs throughout an entire DR event, not just in the first hour.

To deliver these lofty outcomes, the technology behind PCD consists of a two-pronged approach: novel load forecasting techniques at the household level, and a cutting-edge mathematical optimization engine to solve for the optimal dispatch strategy for each individual device.

Forecasting Household Load

A key component of orchestrating the behavior of hundreds of thousands of DERs in concert with one another is the ability to forecast what each household’s demand might look like under different scenarios. To address this, Uplight’s Data Science team developed the PCD Load Forecasting Models—deep learning models trained to predict, with high fidelity, how a home’s load curve will respond to varying DR event start times, durations, and weather conditions. These models are powered by years of training data, including AMI interval data, OEM-provided device telemetry, past DR participation, and high-resolution weather inputs.

To solve the common “cold start” problem, the models leverage learnings from similar homes in the territory when little or no historical data is available. They are also retrained on a regular cadence, allowing them to adapt to changing patterns in customer behavior and seasonal load dynamics over time. The result is a continuously improving forecasting system that accurately anticipates each home’s baseline load and potential DR treatment load, enabling smarter, more personalized dispatch decisions with every event.

Mathematical Optimization for Dispatch

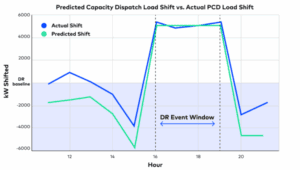

The second pillar of the PCD system is our mathematical optimization engine. Using each household’s personalized load forecasting model and the parameters of the DR event window, we perform a large-scale optimization across the entire fleet of DERs to determine the ideal dispatch schedule for every enrolled device.

The engine’s objective is to maintain a flat aggregate load curve across the full duration of the event, avoiding the typical degradation in load shed performance in later hours. It does this by calculating when each individual household should begin participating—whether in the first, second or third hour, based on its unique thermal and behavioral profile encoded in the load forecasting model for that household. Some homes are capable of delivering sustained load reduction over multiple hours, while others are better suited to shorter contributions. By strategically staggering the event start times of households with different stamina characteristics, the system keeps fresh capacity entering the event just as earlier participants begin to taper off.

This intelligent blending of short-duration and long-duration assets ensures a consistent, reliable load shape across the entire event, turning a diverse fleet of DERs into a unified, dispatchable capacity resource that has similar behavior to a physical power plant.

From Model to Megawatts

By solving the challenge of performance degradation in traditional thermostat demand response, PCD redefines what utilities can expect from residential DERs. It transforms a scattered fleet of devices into a unified, dependable capacity resource that operates with the reliability and predictability expected in the utility control room, enabling grid operators to shift from reactive management to strategic planning, unlocking more efficient market participation and greater grid stability. During a pilot deployment with a North American utility in the summer 2024 DR season, PCD reduced load shift variance by as much as 94% across a four-hour event, demonstrating the level of precision and consistency needed to treat residential DERs as firm, dispatchable capacity.

In addition to delivering value in the utility control room, PCD improves the end-user experience by orchestrating shorter, more targeted events for most devices compared to traditional thermostat DR. This lighter-touch approach helps preserve customer comfort and reduce event fatigue, which in turn keeps customers more engaged over time. In the summer 2024 DR season, PCD events saw up to a 6% reduction in opt-outs compared to traditional approaches, providing an early signal that smarter, more personalized dispatch can lead to stronger customer participation.

While flat, consistent load reduction from a population of residential DERs is a large achievement, the vision for PCD doesn’t stop there. PCD was designed from the start with the flexibility to scale across a wide array of DER technologies, and to meet varying grid objectives. A similar approach used for modeling a thermostat’s response to a temperature setback can be applied to learning the charging behavior of an EV, or the thermal characteristics of a grid-connected water heater. The same optimization engine that schedules a staggered dispatch across thousands of homes can be extended to orchestrate diverse asset classes, and deliver more generalized load shaping. Instead of building custom solutions for every new asset or grid objective, grid operators can rely on a single, adaptable platform designed to keep pace with the rapidly changing DER environment.

For utilities in a quickly-evolving grid landscape, the extensibility of PCD is not only an advantage, but a necessity. PCD transforms demand response from a seasonal, emergency-only lever into a year-round, multi-asset tool for grid orchestration. By turning advanced models into measured megawatts, PCD ensures that a smarter demand stack is not just an aspiration but an operational reality—today and in the increasingly complex grid of tomorrow.