Electrification. Demand management. Renewable energy. The future (and opportunity space) is bright! As consumers, we’re buying electric vehicles and enrolling thermostats (and even water heaters) in demand response programs. Well, with a little help, of course… from contractors.

Consider direct install programs. As utilities and implementers, we can promote these programs, but our reach stops when the contractor takes over. We rely on contractors for smart thermostat installation (and program enrollment in some cases) for income-qualified customers – or even those who prefer not to DIY.

In short, contractors own the end user experience. They’re face-to-face with customers and interacting inside their homes (and with the HVAC system). They have the customer’s full attention. Again, let me repeat this: They have an in-person captive audience!

Let’s stop and see the value here. And the opportunity. How might we leverage contractors being onsite to increase enrollment in demand response programs? First, by understanding the context, goals, and challenges of this very technician who is standing in customers’ homes.

Methodology

The Uplight user research team focused on mechanical HVAC contractors – who specialize in heating, cooling, and ventilation. Pro tip: For those in the business, it’s pronounced “H-V-A-C” (spelled out), not “H-Vac”.

We interviewed 5 HVAC technicians and 2 general managers throughout the US to understand how they operate in customers’ homes. These 7 interviewees worked for contractors of different sizes – from small family-run businesses (your local mom & pop shops) to large wholesalers and distributors. And yes, company size matters.

Differences between smaller and larger contractors

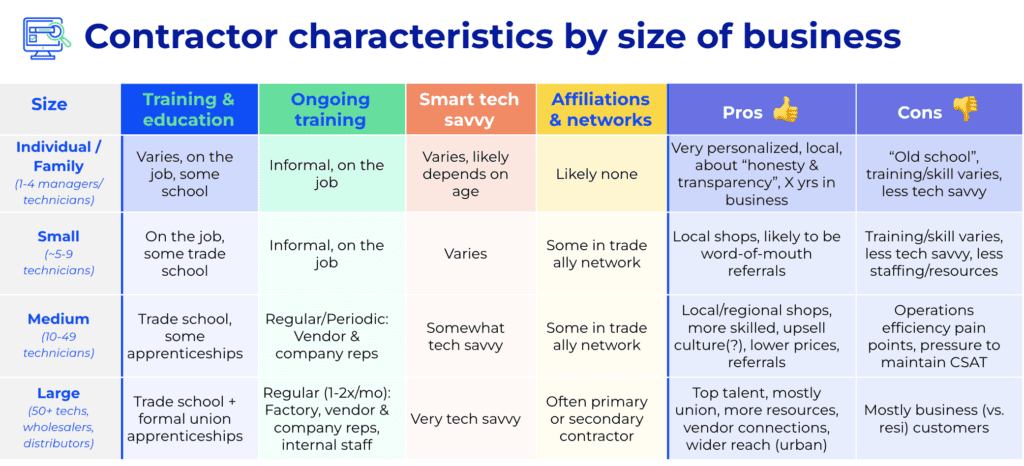

First, let’s define small vs. large in terms of size. Small (including family-run) contractors employ up to ~9 technicians, while medium and large contractors may employ ~10-40 and 50+ technicians, respectively.

Company size is also related to trade ally affiliation status, in-house training opportunities, and to some degree, technician background and smart tech savvy-ness; in essence, all things that impact service design and the end customer experience.

Most local contractors (the ones you’d call when your AC stops working) are small-medium. They’re likely to be word of mouth referrals, are “honest and transparent”, and take pride in their reputation. When inquiring about service, you may speak to the general manager, who’s also the lead mechanic, who by the way, also schedules service appointments. These shops typically have less staffing and resources, and training/skill level varies. Some mom & pop contractors may still track service appointments in paper ledgers (and self describe as “old school”).

Large contractors are often wholesalers and distributors who are often the primary or secondary contractor for utilities and businesses. Their technicians are trade school educated, more experienced and more smart tech savvy than their small contractor counterparts. Speaking of education, large contractors also provide regular, internal training and demos from company and vendor reps (including Emerson, Honeywell, and others). Maintaining operational efficiency and high customer satisfaction are two overarching goals. Not surprisingly, they tend to service business customers and commercial facilities – vs. your average household.

That said, here’s one sentiment to rule them all: “I’m not a salesperson.” Technicians are motivated to get in, get the job done (well), and get out. Fix the problem. Help the customer. Done.

Utility considerations when engaging with contractors

Everyone wins when we meet customers (and contractors) where they are. This should be our collective starting point. Consider this rule #0…

Rule #0: Meet contractors where they are. Consider their day to day: They’ve just replaced a failing compressor, while trying to explain why routine maintenance is key. Oh, and they’re already late to their next appointment, which means they’ll have to contact Dispatch. What would help them do their job? And motivate them to promote utility (demand management) programs?

Rule #1: Provide additional training and education. Not around C wires, they’ve got this – but around smart technology and apps. How to recover wi-fi passwords. Even troubleshoot router issues. Familiarity with Nest, ecobee, and Honeywell apps, for example. How to step through program enrollment and registration.

And, most importantly, provide education around demand management (what it is, net benefits, what’s required). They could (and should) be our advocates!

Rule #2: Provide the right incentives. One technician (at a medium-size business), Rodney, mentioned how his contracting company experienced a huge culture shift. After business ownership changed hands, the new owner implemented a pooled bonus structure. He invited technicians to read the room, and where appropriate, encourage add-ons and upselling that would benefit customers (e.g., maintenance packages, more energy efficient models). And in return, technicians would receive a quarterly bonus based on pooled earnings.

One to two quarters later, Rodney was enjoying an unexpected windfall. “He brought something new to the table … gives us something to look forward to.”